Cadmium Applications

Cadmium pigments

Benefits in brief

Cadmium pigments are highly versatile colouring agents that display the following benefits:

- Excellent and unique full and continuous lemon-yellow-orange-red-maroon colour range with complete intermixability to give mid tones

- Sharp light absorption edges resulting in cleanliness of shade in this key colour space

- Good chemical and physical stability allowing mixing with virtually any other pigment to achieve the desired shades

- Excellent light and weather fastness (including UV)

- Outstanding temperature stability up to 450˚C, rising to >900˚C when suitably encapsulated

- Excellent opacity with high tinting strength

- Insoluble in water and organic solvents with no bleeding or migration in normal use

- Good chemical resistance, especially to detergents, alkalis and some acids

- Easily dispersible and able to be mixed with whiteners to give clean opaque and reduced shades.

Cadmium pigments are stable, inorganic colouring agents that are produced in a range of rich, vibrant shades of lemon, yellow, orange, red and maroon. Few if any other pigments can match the intensity and cleanliness of tone of cadmium pigments, nor their high stability and opacity. This makes them indispensable in certain niche applications for this critical colour space.

Modern cadmium pigments produced in Europe (or produced at ICdA member sites) are carefully engineered products manufactured in regulated chemical plants with full Health, Safety and Environmental permits under Responsible Care management. These pigments have a well-defined crystal structure and engineered particle size, surface area and surface treatment to ensure they are not only correct for colour but also meet extremely low solubility requirements and other key quality and property values.

Cadmium pigments made by member companies of the International Cadmium Association have undergone EU Risk Assessments and are fully REACH registered. They present no significant risk to people or the environment and are thus classified as non-hazardous with no requirement for any hazard labelling.

Cadmium Applications

Key applications

Owing to their unique combination of benefits, cadmium pigments are used in a range of high performance or demanding products and niche market segments. In many of these fields of application, no colourants exist that can match the properties and value of cadmium pigments.

The main application areas are described below – the supply chain requirements dictate that the uses are industrial or professional only, with no direct consumer powder-pigment use.

Ceramic, glass and enamels

The colouration of decorative ceramic, glass and enamel products often depends on the use of cadmium pigments. They are the only pigments available for the bright yellows, oranges and reds required in the colour palette which are capable of withstanding the high temperature firing processes during manufacture and application. Already stable to over 400˚C, the firing range for decoration can be extended to over 900˚C when the cadmium pigment is encapsulated in glass systems. Typical applications include on-glaze colours, porcelain enamels for steel and glass, and colours for flat glass, tumblers and bottles.

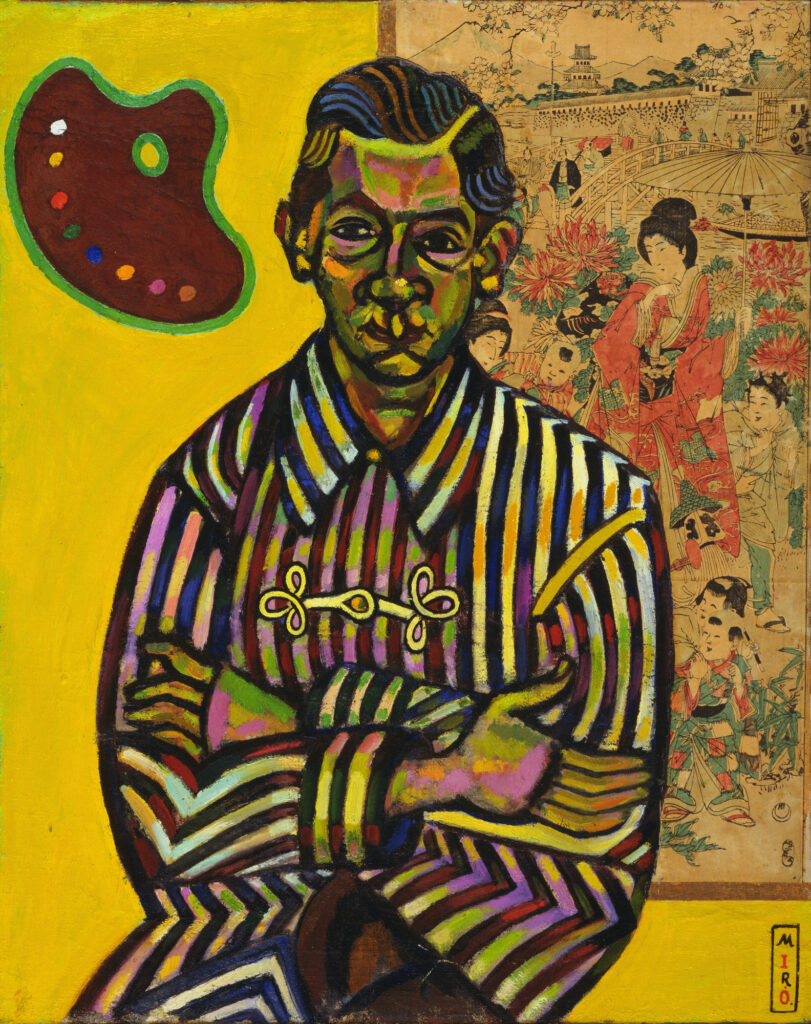

Artists' colours

Coil coatings

Powder coatings

Road markings

Cadmium pigments are ideal for use in road markings where, their unique shade, excellent lightfastness and high thermal stability make them particularly suitable.

Plastics

Their inherently high temperature resistance makes cadmium pigments ideal for polymers such as polycarbonates, nylons and PTFE that are processed at or above 300ºC. This high temperature resistance also enables all moulding sprues and off-cuts to be easily recycled. In comparison, conventional organic pigments tend to start decomposing during moulding and may be unable to withstand further heating.

Cadmium in artist's colours

Cadmium Applications

Three key pigments

Cadmium pigments are processed by calcination at a high temperature to produce a fully crystalline solid solution in stable hexagonal form. Further dispersion and chemical treatment result in highly engineered pigments that undergo strict quality and compliance checks before being placed on the market.

Although a full and uninterrupted range is produced in this part of the colour wheel, it has become convenient for users and regulators to define three representative points in this series, and group the others to those common chemistries, as shown below:

* For EU-REACH administrative purposes, these entries have been assigned as UVCB (Variable Composition) with hexagonal structure and given an alternative EC number of 701-229-5. The compositional formula is CdS1-xSex where x=0.001 – 0.25.

** For EU-REACH administrative purposes, this entry has been assigned as UVCB (Variable Composition) with hexagonal structure and given an alternative EC number of 701-227-4. The compositional formula is Cd1-xZnxS where x=0.001 – 0.46.